WELCOME TO ADG MOBILITY

Leaders in Protected Mobility

ADG Mobility (‘ADGM’) was launched in January 2017 by the same founding members of LMT, which was established in 1999 by Stefan Nell, Chris Giliomee and Andy Hodgson, to focus primarily on design, development and production support of protected vehicles, subsystems and components.

ADGM sees its primary market as clients who are looking for top level protected mobility solutions, including upgrades and MRO (Maintenance, Repair and Overhaul). Our world-class armoured vehicle design and development team is supported by state-of-the-art software, systems and a fully equipped modern workshop staffed by highly skilled artisans.

ADGM’s senior members have on average 30 years of experience and knowledge of design, development, production and support in the field of battle-proven 4x4, 6x6 and 8x8 military armoured vehicles and have, since 1999 together as a team, successfully completed more than 1400 projects spanning over 5 continents.

ADG Mobility’s entrepreneurial culture is fuelled by innovation with quick turnaround times and professional service.

ADG Mobility joined the OTT Group of Companies in 2021

OUR CAPABILITIES

ADG Mobility's business focus and baseline approach.

ADG Mobility specialises in the design, development, manufacturing and support, including midlife upgrades and MRO (Maintenance, Repair and Overhaul) of protected mobility solutions, with the emphasis on 4x4, 6x6 and 8x8 vehicles with high mobility and extreme levels of landmine, IED and ballistic protection.

PRODUCTS

ADG Mobility’s product offerings.

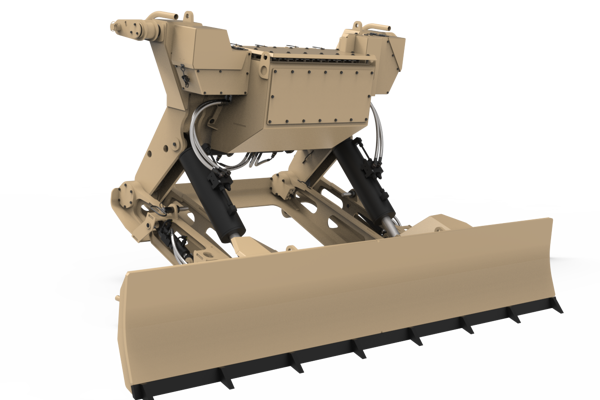

Combat Dozer Attachment

The in-service, stand alone combat dozer attachment can be fitted to wheeled and tracked vehicles for light engineering tasks on the battle field. More than 45 systems are already in service fitted to a MBT (Main Battle Tank) of a Middle Eastern country.

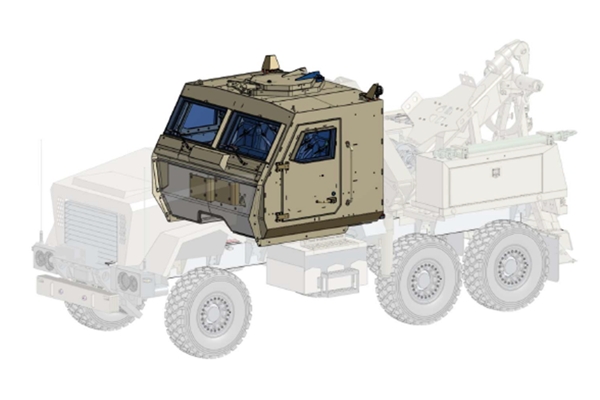

Generic Armoured Cabin

The Generic Armoured Cabin is based on our experience with the design, manufacture and support of more than 200 armoured cabins for trucks for at least two NATO countries. The generic cabin was successfully tested in extreme desert conditions and can be fitted to a wide range of military and commercial trucks.

Spare parts

We supply spare parts to OEMs and End Users for a variety of vehicles and subsystems.

NEWS

View videos and read latest articles about ADG Mobility's capabilities and products.

IDEX 2019: Wahash "Wild Falcon" 8x8 IFV Show Debut

ADG Mobility launches Serbian 6×6 armoured vehicle

ADG Mobility and Serbia’s Srboauto have launched development of a new 6×6 amphibious fighting vehicle called Kurjak (Black Wolf).

SA-designed 8×8 launched at IDEX

United Arab Emirates-based company Calidus has launched its new Wahash 8×8 armoured vehicle at the IDEX exhibition in Abu Dhabi.

ADG Mobility evaluates URAL 4×4 and 6×6 trucks in South Africa

ADG Mobility has over the past couple of months tested 4×4 and 6×6 version of the URAL Next range of trucks at the Gerotek Vehicle Test Facility.

ADG Mobility manufacturing tactical crane for African client

ADG Mobility, which specialises in the design and manufacture of protected vehicles, is manufacturing the first Kone CXT Explorer Tactical Crane System for an African client.

ADG Mobility: the new armoured vehicle kid on the block

Former employees from Land Mobility Technologies (LMT) have created a new armoured vehicle company, ADG Mobility, which is specialising in the design and manufacture of protected vehicles.

DOCUMENTS AND CERTIFICATION

CONTACT US

We look forward to meeting you.

- 371 Asetileen Road, Silvertondale, Pretoria, South Africa, 0184

- +27 12 804 1233

- info@adgm.co.za

Find us on LinkedIn